Bungalow Villa New Aluminium Formwork Profiles System for Concrete Machine

Aluminium formwork is a construction system for forming cast in place concrete structure of a Building. Adto formwork sy

Send your inquiryDESCRIPTION

Basic Info.

| Certificates | ISO9001:2008;CE |

| Thickness | 4mm |

| Application | Highrise Building,Repeat Villas |

| Transport Package | by Pallet |

| Specification | Max width 600mm,Length follow client′s requirement |

| Trademark | ADTO |

| Origin | Wuhan |

| HS Code | 76109000 |

| Production Capacity | 50000sqm/Month |

Product Description

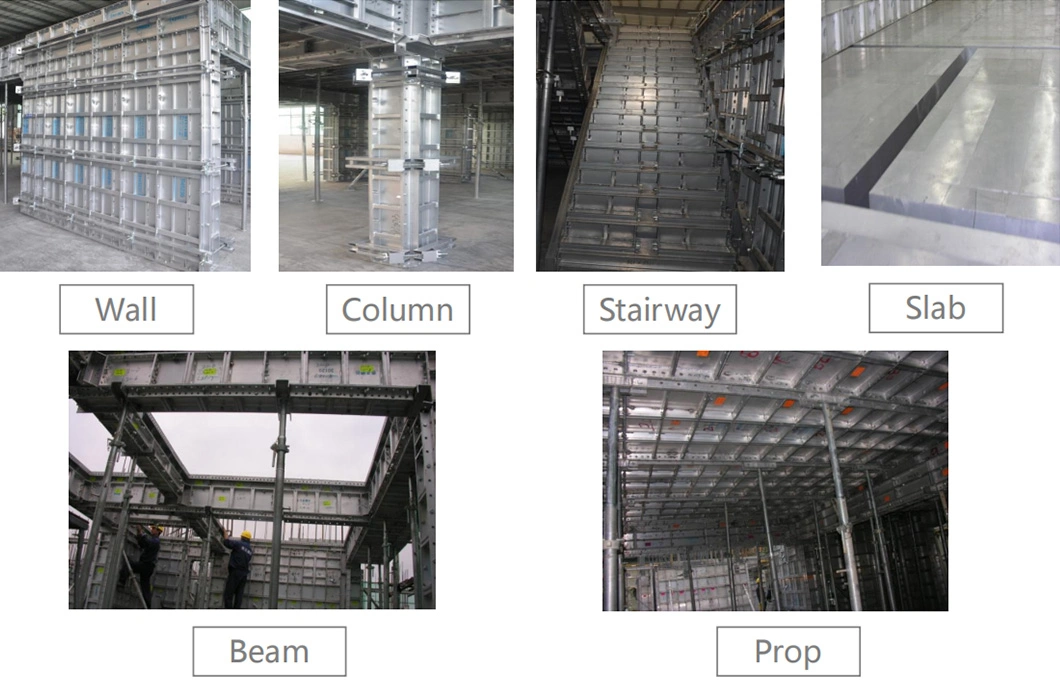

Aluminium formwork is a construction system for forming cast in place concrete structure of a Building. Adto formwork system provides aluminium formwork for RCC, load-bearing, multi-storeyed buildings and enables the vertical and horizontal systems to be poured in the same operation. This increases efficiency, and also produces an extraordinarily strong structure with excellent concrete finish.

Product more details:

| Material type | Complete extrusion | |

| Thickness of panel | 4mm | |

| Thickness of frame | 8mm | |

| Height of frame | 65mm | |

| Average weight | 22-25KG/Sqm | |

| Raw materials | Aluminium alloy 6061-T6 | |

| Standard wall panel width | 50mm to 600mm | |

| Standard slab panel size | 400x1100mm | |

| Surface treatment | Mill finish or Powder coating as client's requirement | |

Advatages of aluminum formwork system:

Light Weight

Made of aluminum alloy 6061-T6,it's average weight is around 25kg/, easy to be carried manually

Flexible Operation

The system can be lifted by tower crane as a whole,or dismantled and installed by labors.It allows casting of wall, beam, slab and staircase monolithically or by two stages.

Long reusing life

The panel is made of extrusion profiles which is high strength and not easy to be deformed or oxidated, the reusing time can reach up to 300 times.

Save labor cost

Panels are connected by pin&wedges, un-skilled labors can install and dismantle the system by hammers only.

Shorten construction period

Early-stripping application improve the system cycle and save cost for users.After pouring of concrete, wall panels could be stripped in 12 hours and slab panels 24-36 hours, finish one floor by four days only.

Improvement of work environment

The system fabricated at factory and requires only installation at site keeps the work environment clean and safe.

Our factory:

Project cases:Product packing and delivery:Exhibition:

Certificates:

FAQ:1.May I use this set of formwork for another project?Yes,there are around 70% of standard panels can be reuse for next project.2.What's your payment terms?T/T 30% in advance and 70% balance against copy of BL, L/ C 100%, or negotiate according to the order status.3.Do you have pre-mocking up service?Yes, we have pre-mocking up service before shipping and make sure do not have problems on site.4.If I don't know well about your system,How to do?Do not worry,professinal technical support will be provided by free.

5.Why choose ADTO?

We are factory

We have professional engineers

We have design team for graphic design & 3D model design

We support custom service: logo, package, panel size, Engineering plan...

Related Products

-

![Aluminium Construction Formwork Stud Pin and Wedge]()

Aluminium Construction Formwork Stud Pin and Wedge

-

![Comaccord Adjustable Steel Prop Metal Shoring Prop Scaffolding System Aluminum Formwork Accessories]()

Comaccord Adjustable Steel Prop Metal Shoring Prop Scaffolding System Aluminum Formwork Accessories

-

![Anchor Nut Formwork Wing Nut Thread Rod Building Material Aluminum Formwork Accessories Conrete Forming Accessories]()

Anchor Nut Formwork Wing Nut Thread Rod Building Material Aluminum Formwork Accessories Conrete Forming Accessories

-

![High Quality Concrete Aluminium Formwork Accessories System of X Flat Tie]()

High Quality Concrete Aluminium Formwork Accessories System of X Flat Tie